Start sawing until the entire traced area has been cut.

With the saw blade, cut in from the drilled hole until you arrive at the edge of your followed shape. Reattach the blade by attaching one end of the blade to your spigot farthest from the handle. Pass the saw frame through the drilled hole. This hole will let you cut out of the inside, so you don’t have to cut through your material to get to the center. At the middle of the drawn region, drill a hole. With a pencil, trace the area you want to cut. Put the blade in a safe location, as you’ll want it shortly. This will release some of this tension and you are going to have the ability to unhook each end of the blade.

When the saw’s blade is connected, remove it by squeezing the saw.

#Coping saw blade sizes how to#

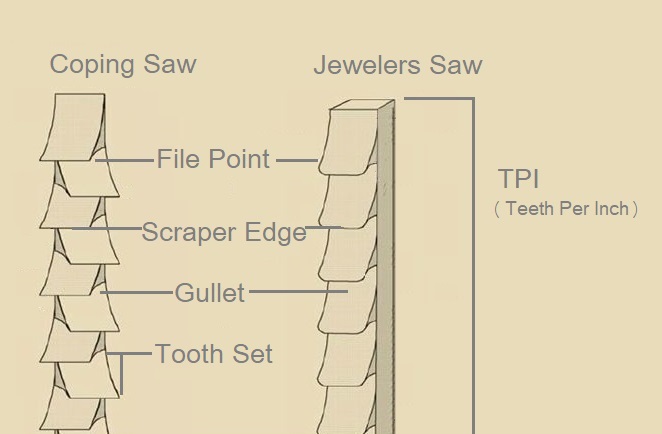

How to Cut a Hole with a Coping Saw Step 1: Remove Blade If this happens, just loosen the blade, replace it, and tighten. Because working saw blades are thin, they will likely break while you saw. If you’re coping molding, you may want to make several passes and begin at the opposite end to complete safely. As you cut, then turn the handle as necessary to follow your drawn route. Step 4: Continue SawingĬontinue sawing vertically to the timber. Push the saw at a quick stroke to initiate the cut. Then set the saw’s central teeth at the onset of the line. If desirable, trace the line you intend to cut onto the wood. Get our final tool and project pairing guide. To use straps, simply open the clamp, set the material inside, and tighten. This will prevent the wood from slipping as you reduce it. Place the material you’re cutting at a vise, or secure with clamps. I do own a larger power coping saw which I rarely use for thicker materials. The Dremel MS20 Moto-Saw is an excellent hobby tool, that should give years of reliable service. There are also high-carbon blades for cutting metal, helical blades for vinyl, and wire blades for the tile. Blade change has been complained about but I find it to be easy after a few times using the saw. For wood jobs, you’ll want to pick out a rough blade, or even those with 15 fewer or teeth. Release tension and adjust as needed.ĭealing saw blades come in many different teeth sizes. Then press down on the grip to compress the frame so the other end of the blade could be attached. Attach 1 end of the blade into the spigot farthest from the handle. Put in the saw blade by setting the front edge on a sturdy surface and holding it the handle points upward. As a bonus, we’ll also show you how you can use a coping saw to cut a hole. That is why we broke the process down into easy-to-follow measures for novices and experts alike. The thin blade of lightweight coping saws makes them perfect for cutting curves and complex designs.Ĭoping saws are not especially tough to work with, but they can be somewhat intimidating. You will want to use a particular tool, known as a coping saw, to ensure a snug fit in corners. If you’ve ever installed molding, then you understand that one of the hardest jobs is coping with the joints.

0 kommentar(er)

0 kommentar(er)